To Our Valued Customers and Business Partners: We are pleased to announce that...

Color is what CTI is all about. Since 1982, it has been the leading powder coating manufacturer in the Philippines, providing state-of-the-art, high-quality color solutions to industrial and commercial manufacturers in the country.

One color defines everything we produce at Chemrez: green. We call it Green Chemistry, a promise to drastically reduce or even eliminate the use of hazardous substances and minimize the generation of it.

Corro-Coat product line is made with high-quality material, and meet demanding global standards. Corro-Coat has the product to meet your specific need.

Avail of Our Customized Color Matching

Using our state of the art spectrophotometer, we will accurately match any shade

Download BrochureNews

COSMIC COLORS LUNA COLLECTION Let moonlight shine with radiant whites, temperate neutral and midnight blacks. DOWNLOAD SOL COLLECTION The smoldering beauty of the sun inspires this set of deep reds. fiery oranges and bright yellows. DOWNLOAD STELLA COLLECTION Galaxies, nebulas, entire universes of color, re-imagined in brilliant metallics. DOWNLOAD TERRA COLLECTION The smoldering beauty of the sun inspires this set of deep reds. fiery oranges and bright yellows. DOWNLOAD

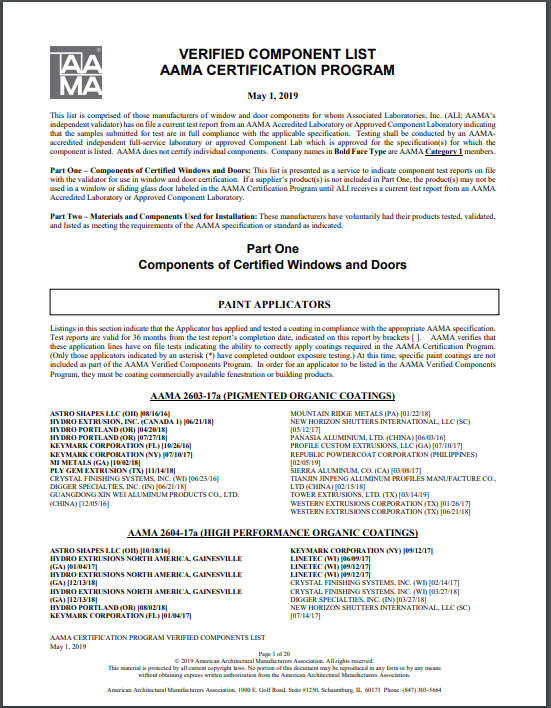

Verified Component List AAMA Certification Program May 2019

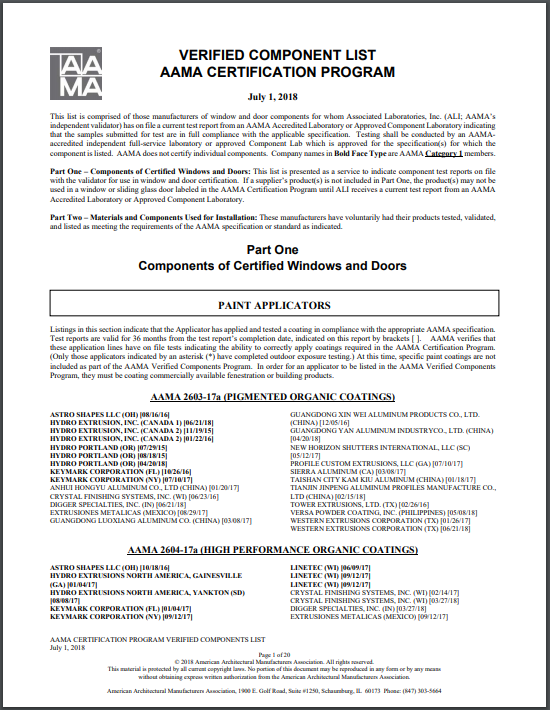

Verified Component List AAMA Certification Program July 2018

Send Us a Message

Please share your details below and we will get in touch with you soon.